Non-Destructive Testing (NDT) is an essential part of the process in assessing the integrity and reliability of materials and components, especially in critical industries such as aerospace, defence, motorsport, and many more.

At Metal Finishings Ltd we specialise in Fluorescent Penetrant Inspection (FPI).

Magnetic Particle Inspection (MPI)

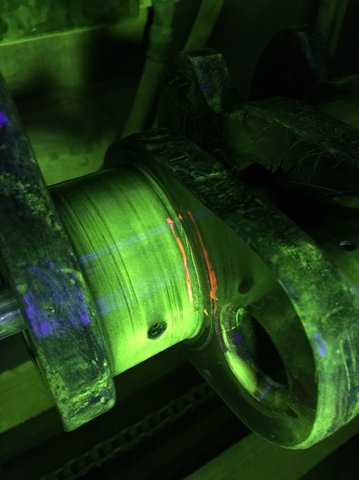

Magnetic Particle Inspection (MPI) is primarily used for detecting surface and near-surface discontinuities in ferromagnetic materials. This technique involves magnetising the part and then applying ferrous particles to the surface. The particles are attracted to areas of magnetic flux leakage, indicating possible defects.

Process

- Preparation – The surface of the component is thoroughly cleaned to remove any contamination that may interfere with the inspection process.

- Magnetisation – The part is magnetised by passing an electrical current through it (current flow) or by exposing it to magnetic field (e.g. a magnet on the surface of the part, the part inside a magnetic coil or a magnet threaded through the part).

- Inspection – The component is inspected under visible and/or ultraviolet light to detect indications where particles have gathered.

- Demagnetisation (degaussing) – Residual magnetism is removed.

Advantages

- Highly effective for detecting surface and slightly sub-surface defects.

- Provides immediate results, allowing for quick decision making.

- Relatively low cost and simple to perform.

Limitations

- Only applicable to ferromagnetic materials - e.g. iron, nickel, cobalt, and some alloys like carbon steel, martensitic, ferritic and some semi-austenitic stainless steels.

- Surface preparation is critical for accurate results.

- Limited to detecting defects that create sufficient magnetic flux leakage.

Fluorescent Penetrant Inspection (FPI)

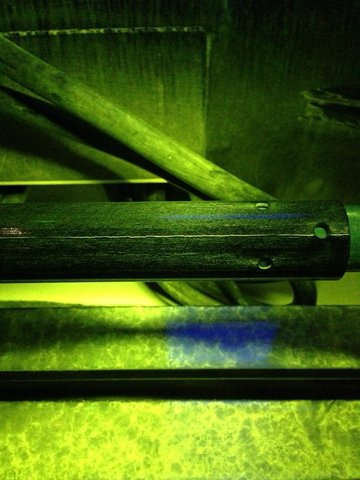

Fluorescent Penetrant Inspection (FPI) is widely used for detecting surface-breaking defects in non-porous materials. This technique involves applying a fluorescent dye to the surface, which penetrates any flaws. After a dwell time, the excess dye is removed, and a developer is applied to draw out the penetrant from the defects, making them visible under UV light.

Process

- Pre-cleaning – The component is thoroughly cleaned to remove any contamination that may interfere with inspection.

- Application of penetrant – A fluorescent dye penetrant is applied to the surface by immersing the part in the penetrant, dwelling to allow it to permeate.

- Excess penetrant removal – The excess dye carefully removed at a specified pressure and distance without washing the penetrant out of any defects.

- Application of developer – A developer is applied to draw out the penetrant from defects to enhance visibility and aid inspection.

- Inspection – The component is inspected under ultraviolet light to identify indications of defects.

Advantages

- Applicable to a wide range of materials, including non-ferrous and non-magnetic materials (including non-metals)

- Capable of detecting very fine surface cracks and defects.

- High sensitivity to small defects.

Limitations

- Surface preparation and cleanliness are critical for accurate results.

- More time-consuming compared to some other NDT methods.

- Requires a controlled environment to prevent contamination and ensure consistent results.

Choosing the Right Technique

Selecting between MPI and FPI depends on several factors, including the material of the component, the type of defects being sought, and the specific requirements of the inspection.

MPI is ideal for:

- Ferromagnetic materials like steel and iron.

- Detecting surface and slightly subsurface discontinuities.

- Situations where quick, immediate results are needed.

FPI is preferred for:

- Non-magnetic and non-porous materials, including metals, ceramics, and plastics.

- Identifying very fine surface cracks and defects.

- Applications requiring high sensitivity to small defects.

At Metal Finishings Ltd our experienced team is ready to help determine the most suitable NDT technique for your components. Contact us today to learn more about our NDT services.